5 industrial applications of laser cutting machines

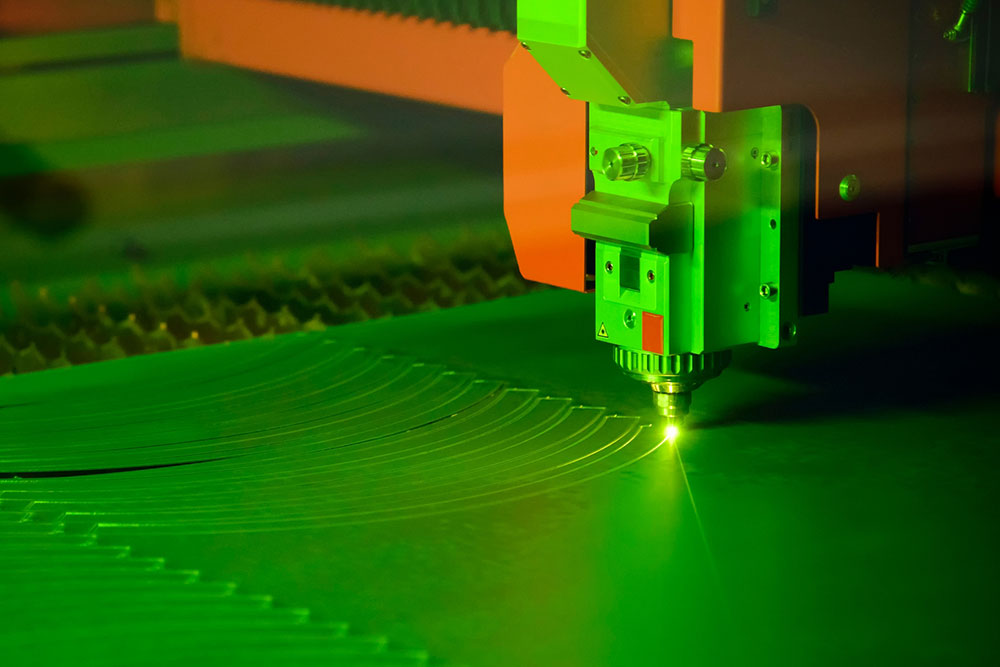

Laser cutting is a technology that uses different types of laser beams to cut diverse materials and objects precisely. Machines that employ this technology offer many benefits over traditional cutting methods. Their precision, efficiency, and versatility make them indispensable tools in many industries. In addition to cutting, these machines are also used to etch and engrave diverse materials. Due to such features, organizations across many sectors are increasingly adopting these machines.

1. Automotive industry

Precision and efficiency are crucial in the automobile industry while manufacturing vehicle components. Laser cutting machines, or laser cutters, have become integral tools due to their capability to meet these demands effectively. The laser cutting technology helps automotive companies bring to life the complex and unique designs they have created for their products. In addition, the higher precision and tolerance levels of the machines help companies meet stringent safety standards. Earlier, the industry relied on stamping and die-cutting to manufacture different automobile components. But, they eventually embraced lasers for their superior features. The different types of laser machines allow automotive companies to create intricate designs and shapes for their vehicles. The technology can be used to manufacture engine parts, exhaust systems, suspensions, die castings, airbags, braking systems, and body panels.

2. Construction industry

This industry employs various laser cutting machines to manufacture structural components. Most components used in the construction sector are huge and complex. Precision and delicacy are crucial while cutting such components, making laser cutters indispensable in large-scale commercial and residential projects. They make the construction of tunnels and bridges easier. Further, the machinery comes in handy when cutting connection plates, base plates, and even composite pieces. The machines can do the job precisely and quickly, helping speed up project timelines. Aside from cutting, laser machines are also used for welding, drilling, engraving, or creating patterns on different building components.

3. Electronics industry

The precision offered by laser cutting machines also benefits the electronics industry. These machines ensure precision and safety while cutting different electronic products, circuit boards, and switchboards. Their application also includes cutting various connectors, enclosures, and heat sinks. Tube laser cutting, a widely used type of technology, helps achieve intricate designs for small electronic components and ensures precise measurements. One of the benefits of laser cutting machines is that their beams do not lose their sharpness or accuracy despite how long the machine has been used. This applies to all the types of laser cutting machines available in the industry. This consistency gives electrical components accurate, smooth, and clean edges. The electronics industry also employs laser cutters to permanently engrave useful information on electronic components. These markings can help identify, detect, trace, repair, replace, and find additional data about the electronic parts.

4. Healthcare industry

Laser cutters play a crucial role in developing various healthcare devices, tools, and daily apparatus with precision. Even advanced healthcare technologies like MRI and X-ray have components that are manufactured with the help of laser cutting machines. Fiber laser cutting machines have found their application in cutting materials that involve tissue, plastic, and bones. This machine is also used to manufacture devices, including surgical equipment. The healthcare sector benefits significantly from such technological advancements. Tube laser cutting machines are used to manufacture devices like stents, heart valves, catheters, and pacemakers. Furthermore, implants, prosthetics, and other components that go inside the human body are crafted with the help of CO2 and other laser cutting machines.

5. Aerospace industry

Quality and precision are critical in the aerospace industry, where even the smallest flaw can lead to catastrophic outcomes. Laser cutters play a crucial role in meeting safety standards as they are widely used in the aerospace sector to avoid potential mishaps. They are used to construct airplane parts, mechanical devices, and various spacecraft components. Laser cutting machines have found several applications in the industry, including metal cutting, engraving of parts, intricate designing, and more. This ensures different aircraft parts are identifiable and traceable. Furthermore, they can even come in handy for quality checks.

The industry uses different types of laser cutting machines based on their raw materials, requirements, and desired end results. Fiber laser, CO2 laser, direct diode laser, and Nd:YAG or Nd:YVO lasers are some of the commonly used types. The type of laser used by a company will also depend on the budget and the space available for the machinery.

In conclusion, laser cutting machines have revolutionized various industries, offering unparalleled precision and versatility. Their ability to handle diverse materials and tasks underscores their role in modern manufacturing and technological advancement across various sectors.